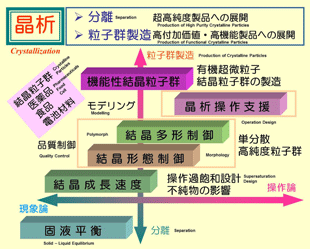

高度に結晶粒子群品質を制御するための晶析のオペレーションデザイン

メンバー: 滝山博志

分野: プロセス・化学工学

所属: 工学研究院

キーワード: 晶析、 Crystallization、 結晶化工学、 Crystallization Technology、 医薬品結晶、 結晶多形制御、 粒径分布制御、 結晶純度制御

ウェブサイト:

研究概要

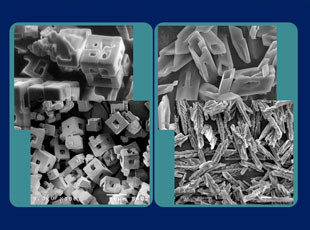

医薬品、食品などで多用されている結晶性物質を生産するための手法、すなわち「晶析操作」に関する研究開発を行っています。結晶性粒子群の品質として、粒径分布、純度、結晶多形、結晶形態などが挙げられますが、それらの品質を高度に制御しながら効率よく製造する技術を研究しています。具体的な研究例は次の通りです。

(1)非溶媒添加晶析(貧溶媒添加晶析)

・非溶媒添加晶析での医薬品結晶の多形等高度品質制御

・オイルアウトする溶液からの結晶成長現象

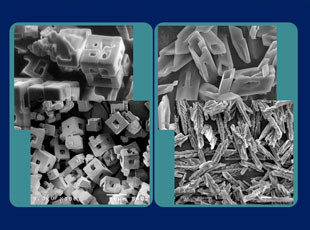

(2)機能性結晶粒子群の創製

・気泡/溶液界面を晶析場とした有機微結晶粒子群の創成

・結晶粒子群の形態をダイナミックに制御するための添加物効果

・ミリ-マイクロ流路と変調操作を組み合わせた微結晶粒子群創成

(3)回分晶析(冷却晶析、反応晶析)

・変調操作を利用した回分晶析の結晶粒子群品質制御とそのモデル作成

・有機塩形成の反応晶析での過飽和操作設計

(4)持続型社会実現のための晶析技術開発

・海水溶存資源回収と有効利用のための晶析操作法

主要論文・参考事項

1) “Control of polymorphism in the anti-solvent crystallization with a particular temperature profile”,Minamisono, T., H. Takiyama, Journal of Crystal Growth, 362 (1), 135-139 (2013)

2) “Production of organic micro-crystals by using templated crystallization as nucleation trigger”, Yamamoto, H., H. Takiyama,Journal of Crystal Growth, 373 (15), 69-72 (2013)

3) “Production of Organic Fine-Crystalline Particles by Using the Liquid-Liquid Interface in an Emulsion”, Takiyama, H., Ito, Kenji, Chemical Engineering & Technology, 35 (6), 991-994 (2012)

4) ”Supersaturation Operation for Quality Control of Crystalline Particles in Solution Crystallization”, Takiyama, H., Advanced Powder Technology, 23(3), 273-278 (2012)

5) “Production of Fine Organic Crystalline Particles by Using Milli Segmented Flow Crystallizer”, Kudo, S., H. Takiyama, Journal of Chemical Engineering of Japan, 45(4), 305-309 (2012)

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Operation Design of Crystallization Technology for Control Crystalline Particles Qualities

Research members: Dr. Hiroshi Takiyama

Research fields: Process/Chemical engineering

Departments: Institute of Engineering

Keywords: Crystallization, Crystallization Technology

Web site:

Summary

Operation design of new technology for producing functional crystalline materials by integrating “crystallization” and crystal engineering is investigated in my laboratory. Research concept and technology are as follows. (1) Crystallization Operation Design: Establishment of the operation design strategy based on crystallization phenomena. (2) Production of new functional crystalline particles: Material development based on molecular self-assembly characteristic. The following researches are underway in my laboratory.

[A] Anti-solvent crystallization: (a) Effects of mixed solvent properties on crystallization phenomena, (b) Effects of operating conditions on particle morphology

[B] Production of functional crystalline particles: (a) CSD and morphology control by using templated crystallization, (b) Effects of additives on polymorph transition and morphology

[C] Batch crystallization (with modulated operation): (a) CSD control by using undersaturation operation

[D] Evaporative Crystallization (with addition water): (a) Controlling of excess fine crystals by using addition water

Reference articles and patents

1) “Control of polymorphism in the anti-solvent crystallization with a particular temperature profile”,Minamisono, T., H. Takiyama, Journal of Crystal Growth, 362 (1), 135-139 (2013)

2) “Production of organic micro-crystals by using templated crystallization as nucleation trigger”, Yamamoto, H., H. Takiyama,Journal of Crystal Growth, 373 (15), 69-72 (2013)

3) “Production of Organic Fine-Crystalline Particles by Using the Liquid-Liquid Interface in an Emulsion”, Takiyama, H., Ito, Kenji, Chemical Engineering & Technology, 35 (6), 991-994 (2012)

4) ”Supersaturation Operation for Quality Control of Crystalline Particles in Solution Crystallization”, Takiyama, H., Advanced Powder Technology, 23(3), 273-278 (2012)

5) “Production of Fine Organic Crystalline Particles by Using Milli Segmented Flow Crystallizer”, Kudo, S., H. Takiyama, Journal of Chemical Engineering of Japan, 45(4), 305-309 (2012)

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)