十字形試験片を用いた二軸引張試験方法による高精度材料モデリング

メンバー: 桑原利彦

分野: 機械工学

所属: 工学研究院

キーワード: plasticity、 sheet metal forming、 anisotropy、 yield function、 constitutive equations、 numerical simulation

ウェブサイト:

研究概要

【なぜ二軸引張試験なのか?】 地球環境保全の観点から輸送機器の高度化・軽量化が加速され、アルミニウム合金、マグネシウム合金、高張力鋼、チタン合金など、成形加工が難しい材料の適用が急増している。結果、割れなどの成形不具合が急増、金型修正工数が増大し、コスト高を招いている。この難点を解消し、軽量化材料の適用を拡大するためには、計算機シミュレーションを駆使して、成形不具合を迅速に事前予測し、トライレス部品生産を図ることが肝要である。

【だから材料モデル】 計算機シミュレーションにおいて成形不具合を高精度に予測するためには、ソフトウェアに組み込まれる材料モデルの高精度化が必須である。そのためには、従来の単軸引張試験方法では不十分であり、プレス部品製造時の実際の応力状態を再現できる二軸引張試験方法に基づく材料試験の実施が不可欠である。

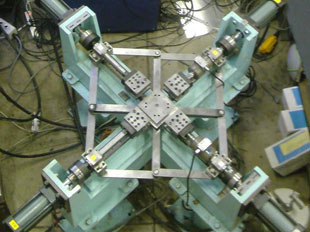

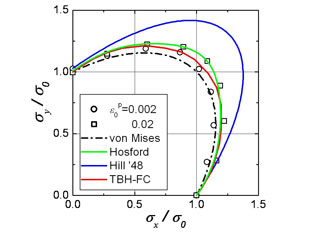

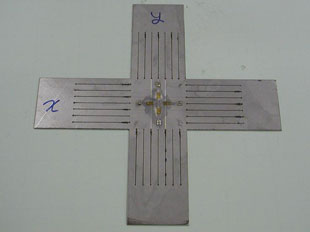

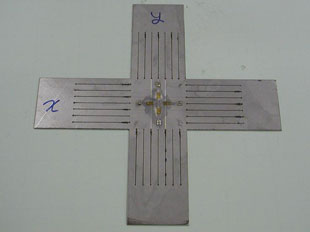

【本試験方法の概要】 サーボ制御型二軸引張試験機により十字形試験片に任意の二軸引張応力を作用させることにより、二軸引張応力状態における金属板材の弾塑性変形挙動や降伏曲面を高精度に測定可能である。これらの測定値は、最適な材料モデルの選定や開発に活用する。

主要論文・参考事項

- Barlat, F., Kuwabara, T.: Anisotropic Yield Conditions in Mathematical Theory of Plasticity, J. JSTP, 57-662 (2016), 230-243. (with Japanese translation)

DOI: http://doi.org/10.9773/sosei.57.230 - Kuwabara, T.:Biaxial Stress Testing Methods for Sheet Metals. In Comprehensive Materials Processing ; Van Tyne, C. J., Ed.; Elsevier Ltd., 2014; Vol. 1, pp 95–111.

DOI: http://dx.doi.org/10.1016/B978-0-08-096532-1.00106-0 - ISO 16842: 2014 Metallic materials −Sheet and strip −Biaxial tensile testing method using a cruciform test piece

- Hakoyama, T., Kuwabara, T.: Effect of biaxial work hardening modeling for sheet metals on the accuracy of forming limit analyses using the Marciniak- Kuczynski approach. In: Altenbach, H., Matsuda, T. and Okumura, D. (Eds.), From Creep Damage Mechanics to Homogenization Methods. Springer, (2015), pp. 67-95.

DOI: http://dx.doi.org/10.1007/978-3-319-19440-0_4 - Kuwabara, T., Ikeda, S., Kuroda, T.: Measurement and Analysis of Differential Work Hardening in Cold-Rolled Steel Sheet under Biaxial Tension, J. Material Process. Technol., 517-523.

DOI: http://dx.doi.org/10.1016/S0924-0136(98)00155-1

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Advanced material modeling based on the biaxial tensile testing method using a cruciform specimen

Research members: Dr. Toshihiko Kuwabara

Research fields: Mechanical engineering

Departments: Institute of Engineering

Keywords: plasticity, sheet metal forming, anisotropy, yield function, constitutive equations, numerical simulation

Web site:

Summary

WHY A BIAXIAL TENSILE TEST? Recently, efforts to make transportation equipment more sophisticated and lighter are accelerating from the viewpoint of preserving the global environment. This has been followed by a surge in applications involving difficult-to-process materials such as high-tensile strength steels, aluminum alloys, magnesium alloys and titanium alloys. However, this has led to a sudden increase in press forming defects such as cracks and springback and additional man-hours are required to modify the dies, which has resulted in increased production costs. To resolve this problem and expand application involving lighter materials, it is critical to predict forming defects at an early stage by computer simulation and eliminate trial-and-error manufacturing.

To predict forming defects with high precision by computer simulation, it is crucial that the constitutive model for the material that is build into the software be made more sophisticated; in other words precision enhancement of the material model is crucial. To accomplish this, the conventional uniaxial tensile test is not adequate. It is crucial to conduct material tests based on the biaxial tensile testing method.

OUTLINE OF THE TEST METHOD: A servo-controlled biaxial tensile testing machine can apply an arbitrary biaxial tensile stress to a cruciform (cross-shaped) specimen. It is possible to precisely measure the elasto-plastic deformation behavior and yield surfaces of sheet metal under biaxial tensile stress. The measurement values are used for selecting and developing optimal material models (yield functions).

Reference articles and patents

- Barlat, F., Kuwabara, T.: Anisotropic Yield Conditions in Mathematical Theory of Plasticity, J. JSTP, 57-662 (2016), 230-243. (with Japanese translation)

DOI: http://doi.org/10.9773/sosei.57.230 - Kuwabara, T.:Biaxial Stress Testing Methods for Sheet Metals. In Comprehensive Materials Processing ; Van Tyne, C. J., Ed.; Elsevier Ltd., 2014; Vol. 1, pp 95–111.

DOI: http://dx.doi.org/10.1016/B978-0-08-096532-1.00106-0 - ISO 16842: 2014 Metallic materials −Sheet and strip −Biaxial tensile testing method using a cruciform test piece

- Hakoyama, T., Kuwabara, T.: Effect of biaxial work hardening modeling for sheet metals on the accuracy of forming limit analyses using the Marciniak- Kuczynski approach. In: Altenbach, H., Matsuda, T. and Okumura, D. (Eds.), From Creep Damage Mechanics to Homogenization Methods. Springer, (2015), pp. 67-95.

DOI: http://dx.doi.org/10.1007/978-3-319-19440-0_4 - Kuwabara, T., Ikeda, S., Kuroda, T.: Measurement and Analysis of Differential Work Hardening in Cold-Rolled Steel Sheet under Biaxial Tension, J. Material Process. Technol., 517-523.

DOI: http://dx.doi.org/10.1016/S0924-0136(98)00155-1

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)