アブレージョンによるめっき被膜損傷の評価

メンバー: 池田浩治

分野: 機械工学

所属: 工学研究院

キーワード: トライボロジー、めっき被膜、摩耗

ウェブサイト:

研究概要

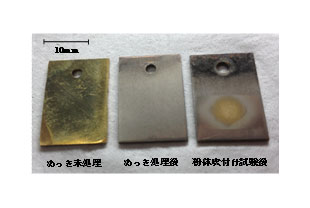

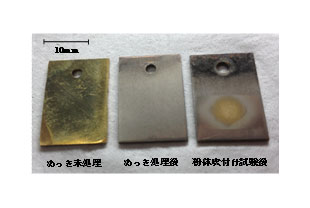

めっき被膜は、耐摩耗性や電気伝導性の向上、防錆、装飾等を目的として、機械部品の表面に施される。またジェットエンジンの空気吸入口、水力発電所のタービン、ポンプ等の流体機械では、流体中の微細な固体粒子が部品表面に衝突して激しい摩耗が発生し(アブレ―ジョン)、機械の性能や寿命を著しく低下させ大きな問題となっている。そこでめっき被膜の耐摩耗性向上のために、微細な固体粒子が含まれた流体(空気または水)を試験材料に吹き付け、めっき被膜にかかる力の測定と材料表面の損傷状態の観察とから、めっき被膜損傷の評価をしている。

以下のテーマのもとに研究を進めている。

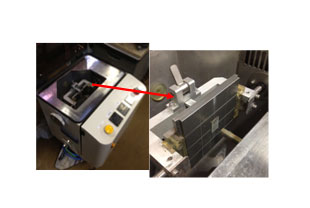

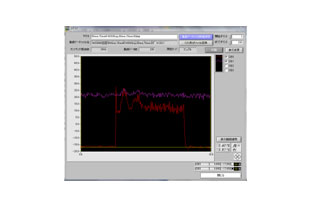

1) 粉体吹付けにおける吹付け力測定方法の改善

2) スラリーエロージョン試験における吹付け角度がめっき被膜の表面形状に及ぼす影響

主要論文・参考事項

1) Relation between Force and Wear in Plated Coating by Slurry Erosion, T. Takatsu, K. Akao, H. Ito and K. Ikeda, Proc. International Tribology Conference, Hiroshima 2011, Oct. 2011, -(-):P04-11

2) Erosion Behavior of Supercritical Nano-plating Nickel on Copper-Zinc Substrate, Koji IKEDA, Takamasa ITO, Kazuhiro KUROZUMI and Hironobu ITO, Transactions of the Materials Research Society of Japan, Jul. 2008, 33(2):351-354

3) Wear properties of nickel coating film plated from emulsion with dense carbon dioxide, Md. Z. Rahman, M. Sone, M. Eguchi, K. Ikeda, S. Miyata, T. Yamamoto, Surface & Coating Tech., Mar. 2006, 201(3-4):606-611

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Evaluation of plating film damage by abration

Research members: Koji Ikeda PhD.

Research fields: Mechanical engineering

Departments: Institute of Engineering

Keywords: トライボロジー,めっき被膜,摩耗

Web site:

Summary

Plating film is performed on the surface of machine parts for improvements of wear resistance and electric conductivity, rust prevention and ornamentation. In the fluid machineries like air intake of jet engine, turbine of hydropower plant and pomp, etc., solid fine particles in a fluid collide with the parts surface and severe wears occur there (Abrasion). It becomes a serious problem because it lowers the performance and life of machine significantly. For an improvement of wear resistance of plating film, a fluid (air or water) with solid fine particles is blasted against a test material, and the damage of plating film is evaluated by a measurement of power applied plating film and an observation of damage condition on the material surface.

Topics for study as follows are carried out in this study.

1) Improvement of blowing force measuring method in the powder spray test

2) Effect of impingement angle on surface profile of plating film by slurry erosion test

Reference articles and patents

1) Relation between Force and Wear in Plated Coating by Slurry Erosion, T. Takatsu, K. Akao, H. Ito and K. Ikeda, Proc. International Tribology Conference, Hiroshima 2011, Oct. 2011, -(-):P04-11

2) Erosion Behavior of Supercritical Nano-plating Nickel on Copper-Zinc Substrate, Koji IKEDA, Takamasa ITO, Kazuhiro KUROZUMI and Hironobu ITO, Transactions of the Materials Research Society of Japan, Jul. 2008, 33(2):351-354

3) Wear properties of nickel coating film plated from emulsion with dense carbon dioxide, Md. Z. Rahman, M. Sone, M. Eguchi, K. Ikeda, S. Miyata, T. Yamamoto, Surface & Coating Tech., Mar. 2006, 201(3-4):606-611

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)