極低濃度電解液と吸引工具による環境対応型電解加工の実現

メンバー: 夏恒

分野: 機械工学

所属: 工学研究院先端機械システム部門

キーワード: 生産加工、加工学、特殊加工、電解加工、放電加工、ポリシング

ウェブサイト:

研究概要

電解加工は、工具無消耗と速い加工速度、高い加工面品質の特徴を有するにもかかわらず、電解液中の漂遊電流による加工精度の低下や、電解液の腐食性と有毒性による作業環境の悪化などの問題点により、応用が限定されています。電解液濃度を極限まで低くすることや、加工領域以外の電解液そのものをなくすことは、上記の加工精度と作業環境の問題の究極的な解決手法といえます。本研究は、内部に流路を設け、吸引によって電解液を工具の端面と工作物の対向部分に限定して流す工具電極を提案し、多品種・少量生産の市場要求に答える高速電解加工を実現します。なお、極間距離により吸引力が変化する現象を利用し、従来困難とされている電解加工における極間距離の検出と制御を実現します。

1.極低濃度電解液による電解加工

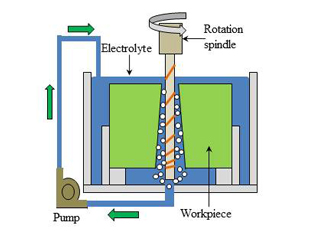

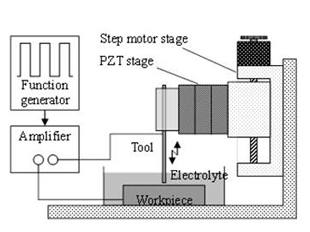

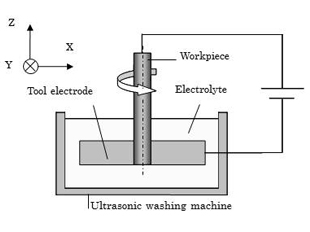

従来の微細電解加工は、酸やアルカリ性の電解液を使用しているので、作業者への危険及び廃液処理による環境問題を伴います。そこで、環境に優れる市販のミネラルウォータを利用した超硬合金微細軸の製作を提案しました。電解質の使用が不要となり、コスト低減や薬品管理の煩雑さの低減など、生産現場において重要な経営課題の解決にもつながります。本研究では、ミネラルウォータの低い導電性を解決するため、従来使用しない100V程度高い電圧を供給できる加工電源を用い、また極間の電流や電圧の変化を検出することにより加工状態をモニタリングし、安定した微細軸を得る可能性を見出しました。

2.吸引工具による電解加工

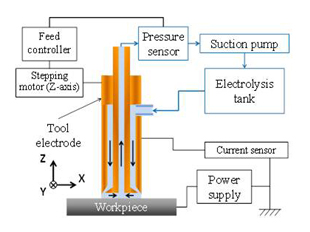

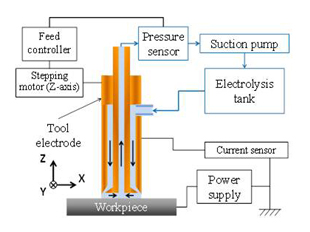

吸引工具は流体力学のベンチュリ効果に基づくものです。工具端面と工作物の距離を小さくしていくと、流れの断面積が狭められ、空気の流速が増加し、ベンチュリ効果により極間の圧力が低くなります。極間の圧力と電解液貯蔵部との圧力差がある程度以上になると、電解液が貯蔵部から吸引され、極間に流れるようになります。この原理を利用すれば、工具の外側に電解液が流れる動力がないため、電解液は工具底面にしか存在せず、また工具の中心部に向かって流れることになります。なお、極間距離と吸引圧力の関係を利用し、吸引ポンプに内蔵されている圧力計を用いて、極間距離の検出と制御ができます。

主要論文・参考事項

1) Ye Yang, Wataru Natsu, Wensheng Zhao: "Realization of eco-friendly electrochemical micro-machining by using mineral water as the electrolyte", Precision Engineering, 35(2), 204-213, 2011

2) Wataru Natsu, Hisashi Nakayama, Zuyuan Yu: "Improvement of ECM Characteristics by Applying Ultrasonic Vibration", International Journal of Precision Engineering and Manufacturing, 13(7), 1131-1136, 2012

3) Naoki Shibuya, Yukihiro Ito, Wataru Natsu: "Electrochemical Machining of Tungsten Carbide Alloy Micro-pin with NaNO3 Solution", International Journal of Precision Engineering and Manufacturing, 13(11), 2075-2078, 2012

4) Katsuaki Endo, Wataru Natsu: "Proposal and Verification of Electrolyte Suction Tool with Function of Gap-width Detection", International Journal of Electrical Machining, 19, 34-39, 2014

5) Dahai Mi, Wataru Natsu: "Proposal of ECM Method for Holes with Complex Internal Features by Controlling Conductive Area Ratio along Tool Electrode", Precision Engineering, 2015 (accepted)

お問い合わせ先

東京農工大学・先端産学連携研究推進センター

urac[at]ml.tuat.ac.jp([at]を@に変換してください)

Realization of Environmentally-friendly Electrochemical Machining with Ultra-low concentration electrolyte and Suction Tool

Research members: Dr. Wataru NATSU

Research fields: Mechanical engineering

Departments: Division of Advanced Mechanical Systems Engineering, Institute of Engineering

Keywords: Manufacturing, Machining, Non-traditional machining, ECM, EDM, Polishing

Web site:

Summary

Electrochemical machining (ECM) technology is widely applied in machining hard-to-cut metallic materials regardless of their hardness. However, the machining accuracy is lower comparing with that in EDM, because machining takes place not only beneath the tool electrode but also around the surrounding area. Also, the acid and alkaline electrolytes used in machining are dangerous to the operators and cause environmental problems. In order to solve these problems and broaden the ECM application, utilizing ultra-low concentration electrolyte and the suction tool were proposed.

1. ECM with ultra-low concentration electrolyte

This study creatively uses the common mineral water as the electrolyte for ECMM and preliminarily performs the experiments to confirm its machining capability in ECMM. The obvious advantage by using the mineral water as the electrolyte can be concluded in the aspect of environment, economy, and system control, etc. It will be promising for the mineral water to be used in the production of MEMS, such as micro pin by the method of ECMM, for it is totally eco-friendly, no pollution, low cost, high efficiency and no corrosion and wear of the machine tool. During the fabrication of the micro pin, high voltage power supply is essential through experimental observation, which is different from traditional ECM. And the micro WC pin in the diameter of 20 to 30 μm is obtained from a 300 μm diameter WC pin in about 10 minutes in this study. Furthermore, in this study, the machining property and potential of the mineral water as the electrolyte are investigated to find out that its response to the ultra-short pulsed power supply is much faster than conventional electrolyte, like NaNO3 and more suitable for the cases using nano-second pulse power supply, in other words, in the micro-ECM.

2. ECM with suction tool

The tool structure and the machining system are shown in Fig.1. When the tool electrode approaches the workpiece, sectional area of the flow channel becomes narrower. In the narrower flow channel, the air flows faster between the tool electrode and workpiece. This makes the pressure lower in the area between the tool and workpiece. Therefore, the electrolyte is suctioned from the aperture, and starts to circulate. No electrolyte flows towards the outer periphery with this method. Also, the gap-width detection and control is realized through monitoring the suction pressure, since the pressure changes with the gap-width. To confirm the above principle, the machining experiments were carried out by drilling a blind hole and generating a complicated shape with the proposed tool electrode and the feed controlling system. As the result, the effectiveness of electrolyte confinement and gap-width detection, also the possibility of shape generation were verified through simulations and experiments.

Reference articles and patents

1) Ye Yang, Wataru Natsu, Wensheng Zhao: "Realization of eco-friendly electrochemical micro-machining by using mineral water as the electrolyte", Precision Engineering, 35(2), 204-213, 2011

2) Wataru Natsu, Hisashi Nakayama, Zuyuan Yu: "Improvement of ECM Characteristics by Applying Ultrasonic Vibration", International Journal of Precision Engineering and Manufacturing, 13(7), 1131-1136, 2012

3) Naoki Shibuya, Yukihiro Ito, Wataru Natsu: "Electrochemical Machining of Tungsten Carbide Alloy Micro-pin with NaNO3 Solution", International Journal of Precision Engineering and Manufacturing, 13(11), 2075-2078, 2012

4) Katsuaki Endo, Wataru Natsu: "Proposal and Verification of Electrolyte Suction Tool with Function of Gap-width Detection", International Journal of Electrical Machining, 19, 34-39, 2014

5) Dahai Mi, Wataru Natsu: "Proposal of ECM Method for Holes with Complex Internal Features by Controlling Conductive Area Ratio along Tool Electrode", Precision Engineering, 2015 (accepted)

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)