Evaluation of plating film damage by abration

Research members: Koji Ikeda PhD.

Research fields: Mechanical engineering

Departments: Institute of Engineering

Keywords: トライボロジー,めっき被膜,摩耗

Web site:

Summary

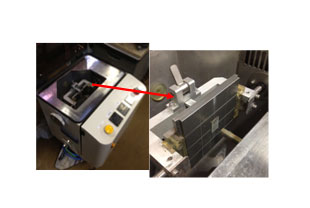

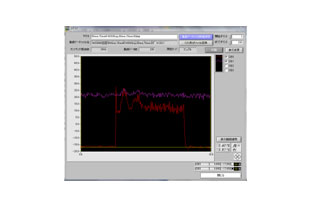

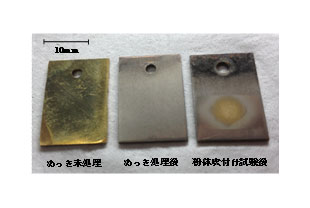

Plating film is performed on the surface of machine parts for improvements of wear resistance and electric conductivity, rust prevention and ornamentation. In the fluid machineries like air intake of jet engine, turbine of hydropower plant and pomp, etc., solid fine particles in a fluid collide with the parts surface and severe wears occur there (Abrasion). It becomes a serious problem because it lowers the performance and life of machine significantly. For an improvement of wear resistance of plating film, a fluid (air or water) with solid fine particles is blasted against a test material, and the damage of plating film is evaluated by a measurement of power applied plating film and an observation of damage condition on the material surface.

Topics for study as follows are carried out in this study.

1) Improvement of blowing force measuring method in the powder spray test

2) Effect of impingement angle on surface profile of plating film by slurry erosion test

Reference articles and patents

1) Relation between Force and Wear in Plated Coating by Slurry Erosion, T. Takatsu, K. Akao, H. Ito and K. Ikeda, Proc. International Tribology Conference, Hiroshima 2011, Oct. 2011, -(-):P04-11

2) Erosion Behavior of Supercritical Nano-plating Nickel on Copper-Zinc Substrate, Koji IKEDA, Takamasa ITO, Kazuhiro KUROZUMI and Hironobu ITO, Transactions of the Materials Research Society of Japan, Jul. 2008, 33(2):351-354

3) Wear properties of nickel coating film plated from emulsion with dense carbon dioxide, Md. Z. Rahman, M. Sone, M. Eguchi, K. Ikeda, S. Miyata, T. Yamamoto, Surface & Coating Tech., Mar. 2006, 201(3-4):606-611

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)