Enterotoxin production and growth of Staphylococcus aureus under various environmental conditions

Research members: Dr. Hiroshi Fujikawa

Research fields: Animal life science, Society medicine

Departments: Faculty of Agriculture, Department of Veterinary Science, Institute of Agriculture

Keywords: Staphylococcus aureus, enterotoxin, growth, raw milk, milk product, environmental stresses, growth model, Time-temperature integrator

Summary of research elements

An extensive Staphylococcus aureus food poisoning outbreak, affecting a total of over 14,000 individuals who ingested low-fat milk products from a dairy company, occurred in Osaka in 2000. Exposure of the raw milk to high temperatures due to a period of power supply loss during product production in a plant may have been the underlying contributing factor that permitted S. aureus growth and subsequent staphylococcal enterotoxin A (SEA) production in the milk.

We quantitatively studied staphylococcal growth and SEA production in pasteurized milk products at a variety of temperatures and then successfully predicted the growth and SEA production of the microorganism in the product.

Then the toxin production in raw milk was studied. That is, two raw milk samples naturally containing low and high levels of natural microflora (NM) were selected. It was found that the optimal temperatures for SEA production in the two milk types were as high as 40°C and 44°C, in the range of 36°C and 48°C, and that SEA production was dependent on the initial dose of S. aureus. These high temperatures were close to that of the outbreak in Japan. Thus, it was concluded that temperature was critical for the SEA production in raw milk. It was also observed that NM in the milk samples considerably suppressed SEA production, but not staphylococcal growth. On the other hand, the amount of toxin in most milk samples decreased after peaking during the storage.

We are studying the mechanisms for the suppression of the toxin production and the inactiovation of the toxin now, leading to find the methods for the control of staphylococcal enterotoxin in milk and other food products.

We also have developed mathematical growth models and evaluated Time-temperature indicators to maintain the microbial food safety of food.

Reference articles and patents

H. Fujikawa and S. Morozumi. 2005. Modeling Surface Growth of Escherichia coli on Agar Plates. Applied and Environmental Microbiology. 71 (12):7920-7926.

H. Fujikawa and S. Morozumi. 2006. Modeling Staphylococcus aureus Growth and Enterotoxin Production in Milk. Food Microbiology. 23:260-267.

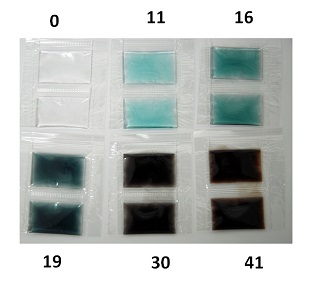

H. Fujikawa and R. Akimoto. 2011. A New Blue Pigment Produced by Pantoea agglomerans and Its Production Characteristics at Various Temperatures. Applied and Environmental Microbiology. 77(1): 172-178.

Sakha M. Zaher and H. Fujikawa. 2011. Effect of Native Microflora on the Growth Kinetics of Salmonella Enteritidis Strain 04-137 in Raw Ground Chicken. Journal of Food Protection. 74 (5): 735-742.

M.Z. Sakha and H. Fujikawa. 2012. Growth Characteristics of Salmonella Enteritidis in Pasteurized and Unpasteurized Liquid Egg Products. Biocontrol Sience. 17 (4): 183-190.

M.Z. Sakha and H. Fujikawa. 2013. Prediction of Salmonella Enteritidis in Pasteurized and Unpasteurized Liquid Egg Products with a Growth Model. Biocontrol Sience. 18 (2): 89-93.

H. Fujikawa, K. Munakata, and M.Z. Sakha. 2014. Development of a competitive model for microbial growth in mixed culture. Biocontrol Sience. 19 (2): 61-71.

H. Fujikawa and M.Z. Sakha. 2014. Prediction of microbial growth in mixed culture with a competitive model. Biocontrol Sience. 19 (2): 89-92.

I.I.Sabike, H. Fujikawa, M.Z.Sakha, and A.M.Edris. 2014. Production of Staphylococcus aureus enterotoxin A in raw milk at high temperatures. Journal of Food Protection. 77 (9): 1612-1616.

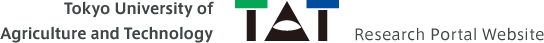

H. Rokugawa and H. Fujikawa. 2015. Evaluation of a new Maillard reaction type time-temperature integrator at various temperatures. Food Control. 57:355-361.

Contact

University Research Administration Center(URAC),

Tokyo University of Agriculture andTechnology

urac[at]ml.tuat.ac.jp

(Please replace [at] with @.)